Welding - Method

BMB packaging machines offer solutions that guarantee perfect container welding and total protection against mechanical and external stress. They are able to weld trays made of different materials, such as plastic, aluminum, cardboard and foam. Solder-only packaging provides packaging that reliably protects the product from physical and environmental stress, moisture and UV light. Soldering alone is a type of packaging particularly suitable for non-food products and industrial, medical and pharmaceutical products or for food that does not require long shelf life. All BMB packaging machines are equipped to pack in welding only and obtain impeccable packages in compliance with the best quality standards.

Modes of use

ATM Packaging Technology

BMB supports the customer in selecting the most suitable solution. Our proposal consists in innovative and customized solutions in every phase of the packaging in Protective Atmosphere to achieve maximum results. The quality of the packaging process in Protective Atmosphere (ATM) plays a fundamental role in guaranteeing the prolongation of shelf life in a natural way.The principle of this technology is to replace the air in the package with a gas mixture. The shelf life of the product is extended up to four, five times or more compared to the shelf life.One of the advantages of packaging in a Protective Atmosphere is that it preserves and increases safety and protection.This type of packaging can be obtained using all thermosealers, thermoforming packaging machines, and vacuum chamber packers, BMB.

Modes of use

Vacuum-packing - Method

Vacuum packaging prolongs the shelf life of the products. The maintenance of the organic product thus has a prolonged life span. With the vacuum technique, the oxidation process is inexorably slowed down. This prevents the development of microbacteria and preserves the product's freshness for longer. Thanks to the vacuum, the product is also fixed to the packaging in order to create additional protection. All BMB machine lines can be used to vacuum-pack any type of material and consistency. A protected and perfectly preserved end product is guaranteed.

Modes of use

SKIN - Method

Imagine that you have just prepared a sauce or a sauce for the first dishes to serve in your restaurant: every chef knows that you can not prepare fresh condiments every day and, for this, it is essential to find the best way to preserve the preparations and avoid losing flavor. To do this, it is essential to use tray heatsealers that can perfectly isolate the preparations and maintain the taste always unchanged. Obviously, it's not just about sauces and condiments: the tray heatsealers are designed to perfectly close trays of different sizes and with different contents. It ranges from the use in small and large restaurants to the use in the centers of production of fresh cheese, and then move on to companies that are involved in the production of preserves of various kinds: similar machinery is a must have for every sector and proves to be a truly indispensable investment.

Modes of use

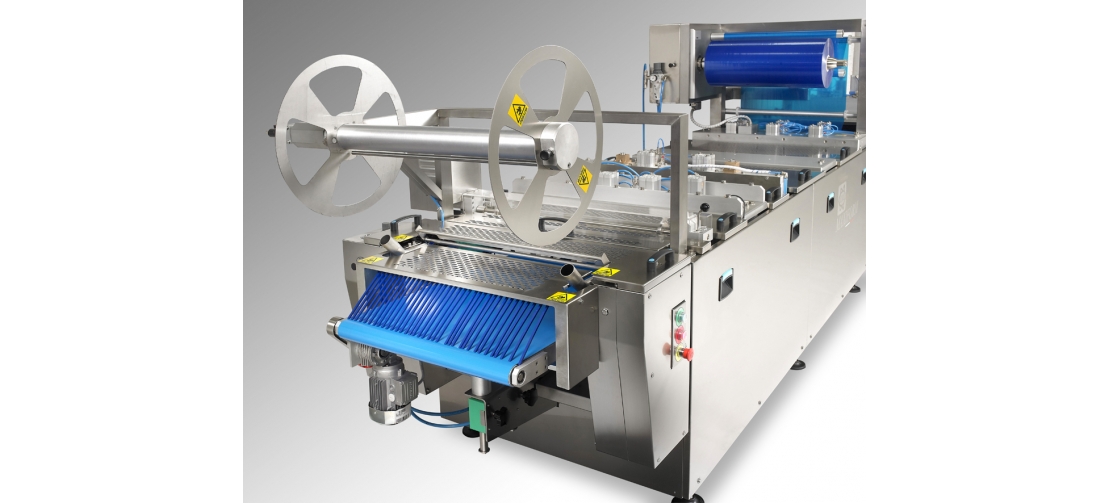

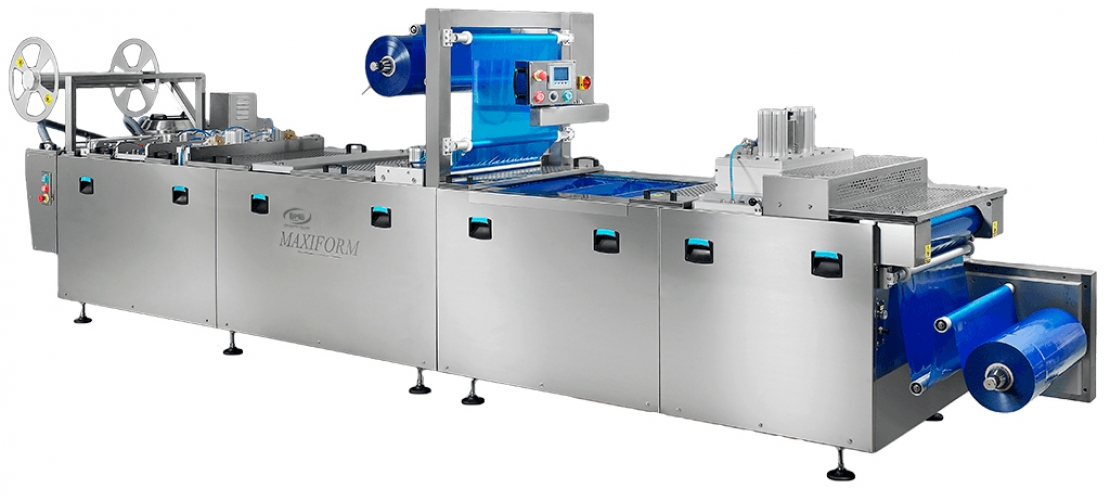

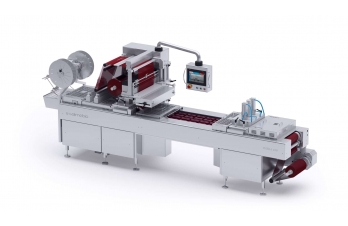

MAXIFORM

MAXIFORM

Fully automatic equipment, which, from a plastic coil (rigid or flexible) creates a lower cuvette to house the product to be made, and then proceeds to the upper sealing of the cuvette. Various types of plastic may be used depending on the product to be made.

Equipment Features:

- Built to ensure quick and easy access to drive controls;

- Collapsible side panels for easy and practical maintenance and cleaning;

- Traction of the belts by three-phase motor, controlled by inverter with speed variation;

- Automatic reel-door structure with pneumatic expansion and axial movement;

- Carrying straps and plastic handle in AISI 304 stainless steel;

- Support rollers on loading stations and station before and after the cutting zone;

- Loading mat with 3 - 4 useful loading steps.

Plastic characteristics (maximum diameters, rigid lower and flexible top film).

• Bottom: up to 1000 mm

• Upper: up to 1000 mm

Main Construction Characteristics

- FESTO Pneumatic Accessories;

- PLC Siemens;

- Color touch screen with the possibility of recording up to 100 programs;

- Temperature of the welding bases and thermoforming programmable through the Touch Screen panel;

- Photocell reading top printed film;

- Safety protections in accordance with the latest European CE marking directives.

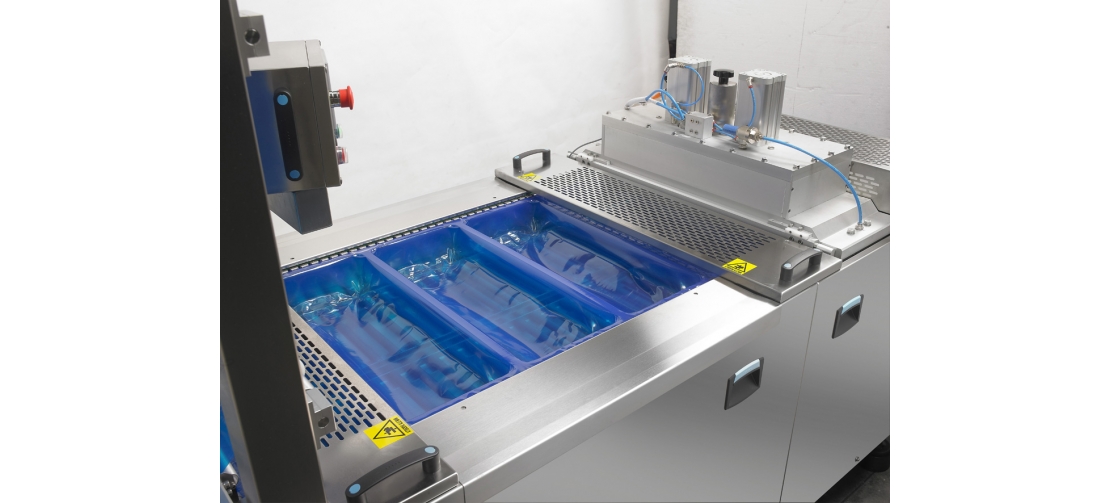

THERMOFORMATION - CONFECTIONING - EVACUATION

• Upper and lower sandwich bases teflonated and heated;

• Mechanically adjustable teflon puncture cap suitable for the formats to be made;

• Movement of molds by means of pneumatic cylinders.

Cortes - Exit, Confection and Recovery of Plastic Waste

• Hard plastic cutting

• Flexible plastic cut

• Adjustable product exit mat

• Collection of waste by motorized winders.

Pump vacuum

• Busch vacuum pump 100 mc / h mounted inside the equipment.

Peel-Off

• Optional device for the use of peel-off easy-peel plastic for easy opening of the packaging.

Gas Injection (Protected atmosphere packaging)

• Group for the injection of complete gas of injection nozzles and safety lung with electronic management of the injection phase combined with the creation of

Lower Film Width

490 - 550 mmMáxima Profundidade Formada

80 - 200 mmMax. Formed Depth

400 mm34/5000 Upper Coil Max. Diameter

350 mmDiameter of Coil Holder

2" - 70 mmElectric Supply

400V 50/60Hz 3PH+N+PEPower

7 - 40 kWCompressed Air

6/8 BarWater Consumption

2 Bar - 60/120 l/hConsumables

Here you can see the list of all the consumables we have at your disposal