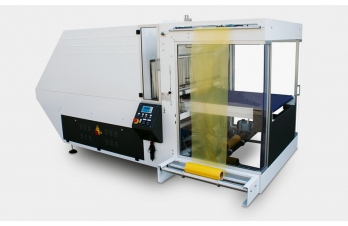

Fully automatic, the ECOFARD AOL sleeve-wrapper machine has lateral feeding for “multipackage" (several products wrapped up together on several lines) without an operator. Practical high-speed sleeve-wrapping machine able to package a wide range of products (bottles, vases, jars, pots, cans, phials, cases etc) and to shelter boxes integrating and/or replacing the use of carton boxes at end-of-line with great management advantages.

The machine is compact and consists in a sealer and a tunnel; it works in a very simple way: a motorized in-feed belt conveyor, situated at 90 ° from the sealing bar, drives the products from the loading area towards the sealing area. Then a transversal sealing-bar (that has a pneumatic movement and temperature is electronically controlled) cuts and seals the film.

At this point the wrapped product enters the tunnel for shrinking. Ideal for high outputs.

Features:

-

LATERAL automatic feeding;

-

Sealing time electronically adjustable;

-

Sealing-bar with two sealing blades and one teflon-coated cutting blade controlled by electronic thermo-regulator ; pneumatic movement;

-

Product detected by a system of photocell;

-

The wrapped product stays on a plate behind the sealing area untill the outcoming wrapped product pushes it onto the tunnel belt conveyor that is always running;

-

In-line in-feed belt conveyor running with fixed speed;

-

Tunnel steel zinc-coated mesh belt conveyor;

-

Tunnel air heating by finned resistances controlled by an electronic thermo-regulator;

-

Closed and forced air circulation with air flow adjustable by flaps in order to have the best shrinking;

- Cooling fan at the tunnel exit included;

- Internal tunnel parts made by steel zinc-coated;

-

External powder painting;

-

Double-rolls system with motorized top and bottom film-unwinding.

Options:

- Customized in-feed belt conveyor;

- Vertical rollers to compress the film excess at the tunnel exit;

- Customized tunnel and sealing-bar height;

- After-sealing-bar top-clamp to block unstable products;

- Frequency AC engine controller for tunnel belt conveyor;

- Discharging idle roller conveyor;

The machines works with single-wounded (flat) LLDPE

Machine made according to CE rules.

Dimensions

4200 x 1500 x 1800 mmTunnel Entrance Dimension

700 x 410 mmTunnel Width

1400 mmDimensions of Cross Welding

700 mmWelding Bar Opening

330 mmMax. Depth of Product

400 mmProductivity

240 - 480 Peças/HoraMax. Coil Height

6500 mmSpeed of the Conveyor Belt

4 m/MinElectric Supply

380 V 3 Ph + NPower

18 Kw