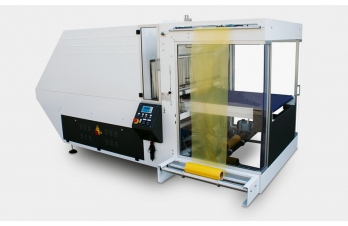

The ECOFARD 700 sleeve-wrapper machine with semiautomatic feeding to make even more multipacks of different size of various products (bottles, vases, jars, pots, cans, phials, cases etc) and/or to protect boxes integrating and/or replacing the use of carton boxes at end-of-line with great management advantages.

Two different models are available: compact (MB) where the tunnel is connected with the sealing area, and sealer-plus-tunnel (BB) where the sealing area is independent from the tunnel.

ECOFARD 700 is compact, the tunnel is connected with the sealing area and the conveyor belt is sincronized with the sealing conveyor belt area. The machine works in a very simple way: from the loading area the products move towards the sealing area, where a transversal sealing-bar (that has a pneumatic movement and temperature is electronically controlled) cuts and seals the film. At this point the wrapped product enters the tunnel for shrinking. Ideal for medium-high outputs.

Features:

- Automatic feeding;

- Double-rolls system;

- Sealing time electronically adjustable;

- In MB models movement of the tunnel belt conveyor synchronized with that of the sealing bar in order to sleeve-wrap also unstable products without a tray;

- In BB models the wrapped product stays on a plate behind the sealing area till the outcoming wrapped product pushes it onto the tunnel belt conveyor that runs continually;

- Cooling fan at the tunnel exit included;

- Tunnel steel zinc-coated mesh belt conveyor;

- Air heating by finned resistances controlled by an electronic thermo-regulator;

- Closed and forced air circulation with air flow adjustable by flaps in order to have the best shrinking;

- Internal tunnel parts made by steel zinc-coated;

- External powder painting;

- Discharging idle roller conveyor included ;

Options:

- Vertical rollers to compress the film excess at the tunnel exit;

- After-sealing-bar top-clamp to block unstable products;

- Frequency AC engine controller for tunnel belt conveyor;

- Motorized bottom film-unwinding;

- Tunnel belt conveyor 800 mm longer for wrapping bottles without any carton tray.

The machines works with single-wounded (flat) LLDPE

Machine made according to CE rules.

Dimensions

1900 x 850 x 1680 mmTunnel Entrance Dimension

480 x 340 mmTunnel Width

730 mmDimensions of Cross Welding

500 mmWelding Bar Opening

240 mmProfundidade Máxima do Produto

300 mmMotorized Coil System

Top CoilSpeed of the Conveyor Belt

ContinuousCompressed Air

6 barMax. Coil Height

480 mmElectric Supply

230/380 V 3 PhPower

6,5 Kw